Thermal Systems

Heat treatment equipment working with different types of convection, if required also reinforced by infrared heaters. UV curing ovens for different applications. For drying of different varnish types, curing of casting materials and glues. Available with different horizontal and vertical conveyor types. Designed for manual or automatic loading and unloading at front and exit side. Cooling processes with ambiant air or reinforced systems working with heat exchangers.Room saving installations integrated in main hosuing. Maintenace free chains and bearings for highest productivity and reduction of maintenance down times.

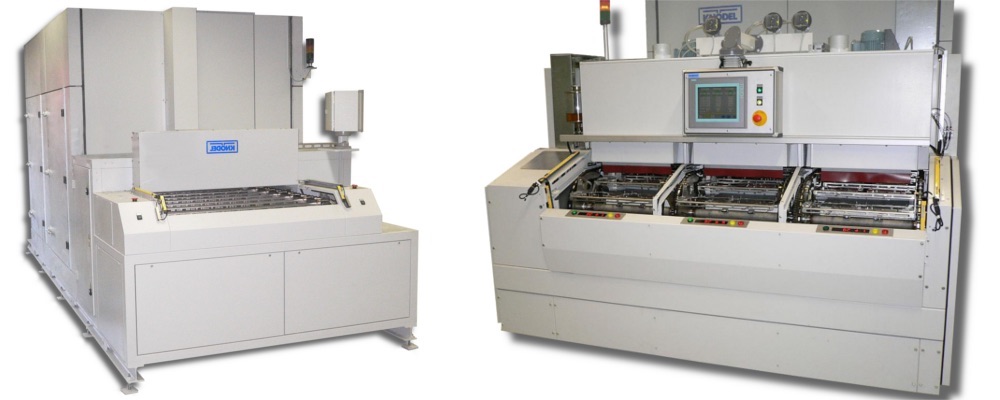

horizontal systems

entuca

KNÖDEL entuca

Capacity

small

medium

high

Temperature

- 50°C

- 100°C

- 150°C

- 200°C

- 250°C

- 300°C

Highlights

- Heat treatment for most puposes with horizontal troughput

- also as single cooling zone

- low-maintanance and easy service

- suitable for manual operation and automatic loading/unloading

- also available without conveyor system

KNÖDEL pentherm-H

Capacity

small

medium

high

Temperature

- 50°C

- 100°C

- 150°C

- 200°C

- 250°C

- 300°C

Highlights

- as pentherm HV suitable for highest capacity and heavy products

- available with cooling zone

- different temperature-zones possible

- low-maintanance and easy service

- suitable for manual operation and automatic loading/unloading

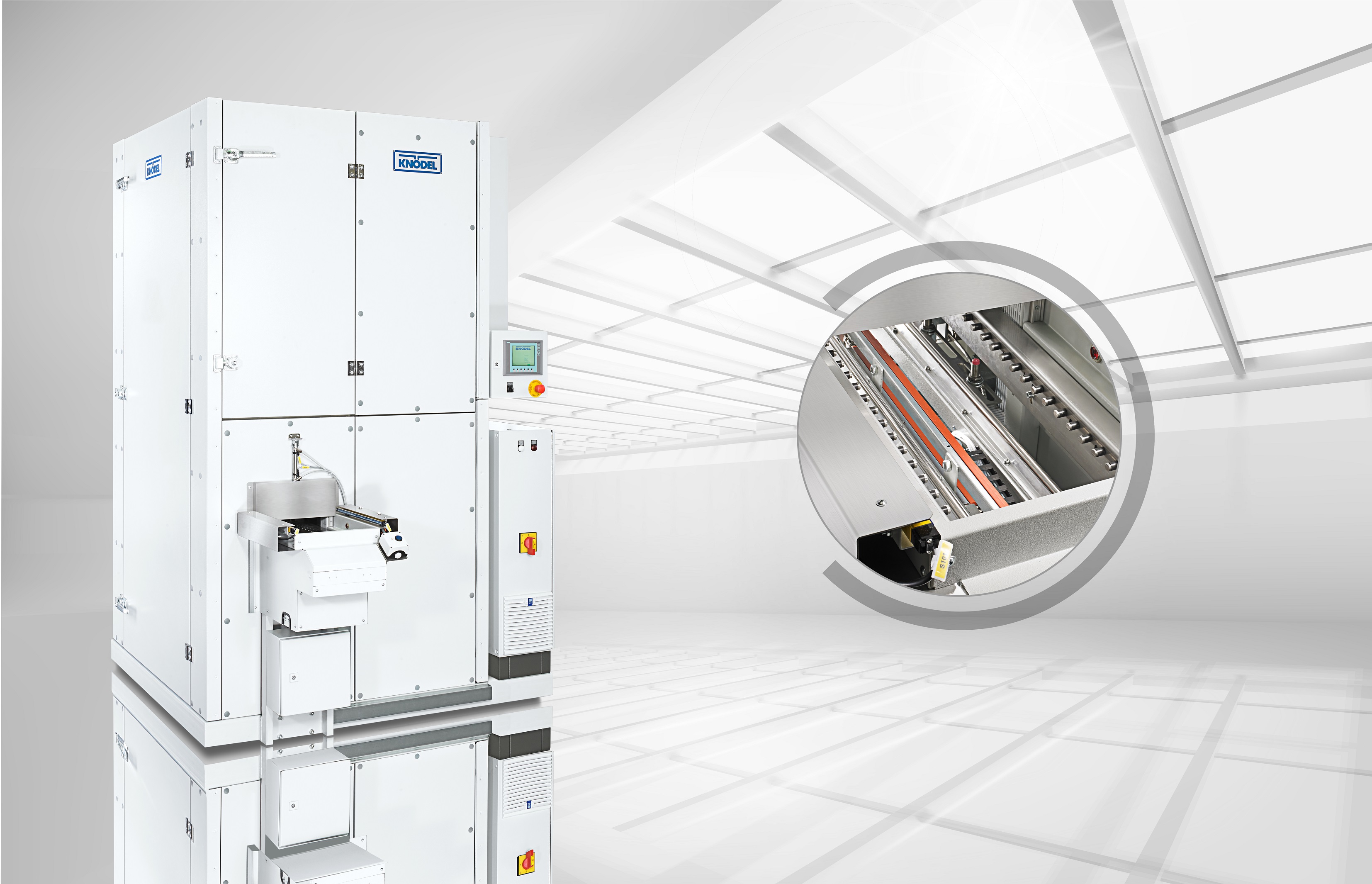

vertical systems

vertan

KNÖDEL vertan

Capacity

small

medium

high

Temperature

- 50°C

- 100°C

- 150°C

- 200°C

- 250°C

- 300°C

Highlights

- suitable for manual operation and automatic loading/unloading

- fast heat-transfer for long dwell-time at set-point temparature

- minimal surface required

- integration of high perfomance cooling zones possible

KNÖDEL pentherm-L

Capacity

small

medium

high

Temperature

- 50°C

- 100°C

- 150°C

- 200°C

- 250°C

- 300°C

Highlights

- suitable for manual operation and automatic loading/unloading

- fast heat-transfer for long dwell-time at set-point temparature

- minimal surface required

- different types available